Under the Health and Safety at Work Act 2015 (HSWA), every business has a responsibility to ensure, so far as is reasonably practicable, the health and safety of workers, and that others are not put at risk by the work of the business (for example, customers, visitors, children and young people, or the general public), so a risk assessment is vital.

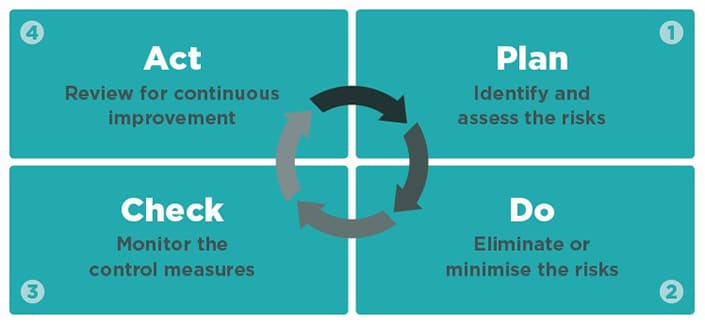

Worksafe have set out the following framework for managing health and safety risks:

More details about each of the steps is available here on the WorkSafe’s website.

Rather than go over the well-worn ground of managing the wider health and safety risks of a business we wanted to look specifically at how to mange the risks in relation to hazardous substances.

While, many general health and safety risks can simply be eliminated with a little effort, often hazardous substances are difficult to eliminate as it is their hazardous property that makes them useful. For example, hydrochloric acid is useful because it is a strong acid and highly corrosive, simply eliminating it would mean certain industrial processes would not work. Consequently, many businesses need to learn to live with the potential risks and take steps to minimise these risks as best as possible.

The difficulty we often see in the workplace is that many businesses are unaware or underestimate the potential risks of the hazardous substances they use. This is made more difficult by the fact that many of the potential health effects of exposure are chronic rather than acute and may take years or decades to show.

Further, as our understanding of the long-term health effects for certain chemicals improves, we often see greater controls recommended. Roundup is the most high-profile example currently in the news with an increasing body of evidence suggesting a link between exposure to the product and non Hodgkin lymphoma.

Currently, Worksafe are also seeking feedback on changes to the Workplace Exposure Standard (WES) and Biological Exposure Index (BEI) for around 34 chemicals and in most cases the exposure standards are reducing. This all supports the notion that we’re better to take a precautionary approach to the safe handling of hazardous substance and avoid inhalation, skin contact or accidental ingestion, even if you believe and your experience is that the chemicals are rather benign.

With all this in mind here are some actionable tips to help mitigate the risks associated with hazardous substances:

Storage:

Store hazardous substances in specific hazardous substance storage cabinets which comply with the relevant Australian and or NZ Standards. This allows goods to stored away from unauthorised personnel and incompatible substances.

Respiratory Protection:

Inhalation is common method of exposure for workers and it is important that workers use the correct respirator and filters for the chemicals they’re working with.

Respirators should be issued to specific workers (not shared), be properly fit tested and the correct filters supplied and changed regularly. It should be noted that disposable masks rarely pass quantitative fit testing and should only be used for very low hazard contaminants.

Chemical Protective Coveralls:

Your skin is your largest organ and you should avoid contact with most chemicals in order to eliminate the risk of absorption. Not all chemical suits will protect against all chemicals so it’s important to understand whether the chemical suit you’re using is suitable for the chemicals your workers are exposed to.

One of the secondary risks when wearing chemical suits is heat stress so you need to take this into account and limit the time that workers are required to wear a chemical suit or consider implementing a hydration program.

Make sure workers know how to inspect and care for chemical suits that are re-usable is important so they don’t accidently put themselves at risk by wearing a chemical suit that is damaged or contaminated.

Gloves:

Just like chemical suits, not all chemical gloves provide a barrier to all chemicals and it’s important that you choose the glove that suits the chemical’s you’re working with. Most reputable glove and coverall manufacturers and distributors will be able to tell you the best protective apparel for your job.

Emergency response:

Be prepared for a chemical emergency, ensure worker know what to do in the event of a spill, leak or contamination. Safety Data Sheets should be readily available along with emergency showers and eyewashes, spill kits and fire extinguisher. Have a written plan in place and test it at least annually.

Signage:

Ensure the appropriate signage is on display for the hazardous substances you have on site. While there are detailed standards available and general rule of thumb is that someone entering the worksite should be easily able to see that certain hazardous substances are on site and be told of any areas they are not allowed into. Furthermore, fire and emergency services must be made aware of the potential dangers as they enter the property.

In short, if your business stores or uses hazardous substances you need to make sure you have completed a thorough risk assessment. SDS sheets are useful place to start.

We strongly suggest you take a precautionary approach as many of the long-term health impacts of chemical exposure, even at low levels are still not well understood.

Here are some useful links if you’re about the review your risk assessments for the hazardous substances you deal with.

- What does risk look like in your industry?

- Hazardous Substance Calculator

- Workplace exposure standards and biological exposure indices

For more information about your requirements and or to talk through how we can help, contact us on 0800 323223, enquiries@ph7.co.nz or via the website.